|

|

| About us |

We are ISO-9001:2000 certified manufacturer of pipeline valves and strainers. Our market focus includes Strainers, ie. Y, Basket, Tee, and Temporary Strainers etc; Check Valves, ie. Horizontal Swing Check, Silent Check, Double Door Wafer Check, Wafer Swing Check, Elastic Swing Check etc; Pump protection products, ie. Cast Iron Triple Duty Valves and Suction Diffusers; Resilent Seated Butterfly Valves; Ball Valves. etc.

Materials used include Cast Iron, Cast Steel, Cast Stainless Steel and alloys etc. Standards include ANSI, AWWA, BS, CEN, DIN, GB, ISO, etc. Pressure rating includes 125Lb, 250Lb, 150Lb, 300Lb, 600Lb and equivalent. Our products have a good reputation in USA, CANADA, EUROPE, AISA, Mid EAST markets.

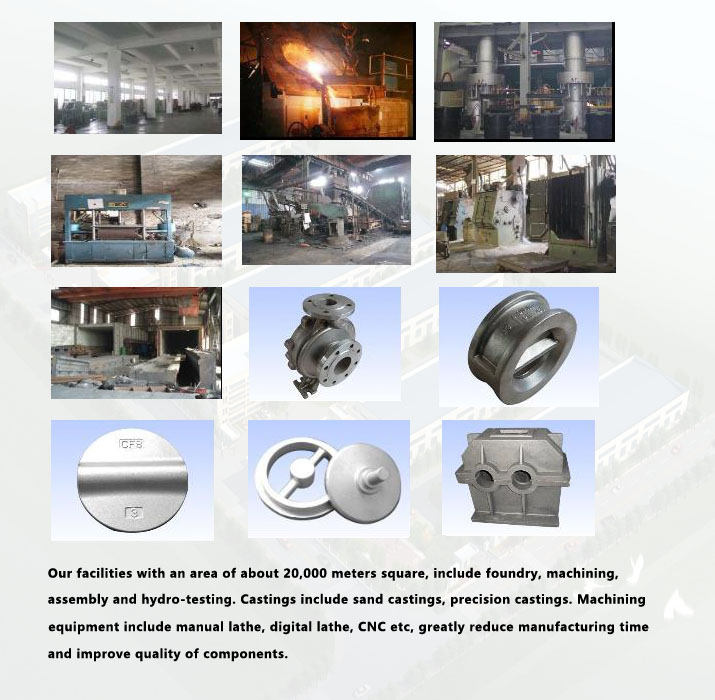

We also have an Iron and Steel foundry, sand castings and precision castings are both in our fields, OEM or ODM are workable for us. Based on all technical know-how, capacity and decades of years experience, we are confident and enthusiastic to cooperate with you. |

|

|

MISSION |

|

QUALITY |

|

CERTIFICATION |

|

|

MISSION

Environmental

We take environment as very important for us and our aim is to produce more and more valves which benefit for the environment for all of people. Therefore we have our rubber of valve qualified for water work requirements of many countries, we have our painting qualified for NORSOK, we have our valve opening or closing with the lowest possible torque to save the energy.

Customer Satisfaction and Long term Relationship with Customers

Customer satisfaction is the measurement of our success and customer fulfillment is the responsibility of each employee of our company. We pursuit partnership and long term cooperation with our customers. We learn about customer needs and wishes. We try our best to save time and money for our customers. We offer innovative products and individual solutions for our customer¡¯s special needs.

Employees¡¯ Qualification and Motivation

We have our employees well trained, well informed and highly motivated. With precise training and regular internal communication the achievements continuously improve the potential of our company. The quality ideal of all employees are promoted.

|

| |

QUALITY

Incoming Inspection

Besides visual, functional and dimensional examinations, we also inspect the rubber shore hardness, rubber thickness, and analyze the metal and rubber Chemical composition through our laboratory.

In-production Inspection

In the production line quality securing inspections will be done on the basis of operator self control. The operator will be supported by the quality assurance employees.

Painting thickness is measured for every layer.

Assembly Inspection

At the assembly line all mounted valves have to pass the tightness test. For butterfly valve, we also make torque test for every pc and have record which would be saved in our company documentation for more than 10 years.

Final Inspection

All valves after assembled need pass the final inspection. In the final inspection section, the finished valves will be inspected for conformity to the customer requirements. Only if all products specification conform to the order documents the valves can be input to the ERP system and be released for the shipping section. |

| |

CERTIFICATION

CQC ISO9001,DNV PED CE, DVGW rubber seat approval, KTW rubber seat approval, WRAS rubber seat approval, FDA rubber seat approval, NORSOK marine surface requirements, etc.. |

|